Case Six

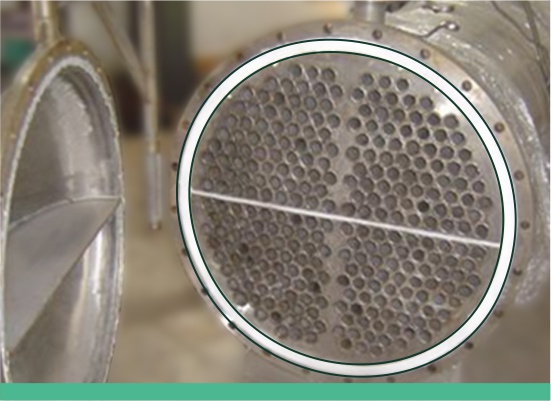

Application of DSF700 in Heat Exchangers

T: 150℃~200℃ P: 0.4-0.5Mpa

Problems Encountered:

The customer used metal wound gaskets for sealing in heat exchangers, but faced the problems of uneven sealing surface caused by processing, complicated installation, long downtime and erosion of sealing surface by high temperature steam. To solve these problems, the customer came to us.

Solution and Customer Benefits:

We recommended the use of DSF700 reinforced expanded polytetrafluoroethylene (PTFE) sealing material. DSF700 tape is soft, compressible and easy to form, and can effectively adapt to uneven and damaged sealing surfaces, ensuring good sealing performance and reducing the risk of leakage. It is also highly fibrous and uniformly distributed, with excellent creep resistance and resilience, and can be used stably for long periods of time in high and low temperature cycling, reducing downtime.