Case Five

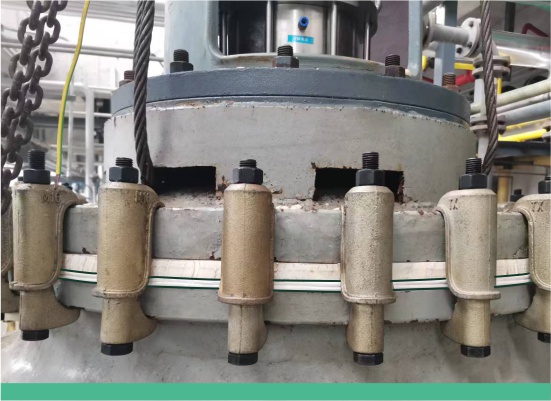

Application of DSF200 in Enamel Reactors

Problems Encountered:

A factory was experiencing a leak in an enamelled reactor, which was occurring at the point where the ePTFE sealing strip was being used. The customer understood the performance advantages of ePTFE material, and knew that it would not cause seal failure due to corrosion in this application, but still could not accurately determine the real cause of the leak. After field investigation and confirmation by our professional and reliable technical support team, it became clear that the problem stemmed from a faulty installation of the sealing strip.

The low quality ePTFE material had been over-compressed by the high locking force and had caused a degree of flange loss, leading to the leak. This problem seriously affects the normal operation of enamelled reactors and requires timely and effective repair and solution.

Solution:

In order to solve the problem, we recommended DSF200 enhanced sealing strips to the customer as a substitute, while our technicians worked directly with the customer's maintenance staff during the shutdown period, providing free training and supervising the installation.

Customer Benefits:

By using the higher quality DSF200 reinforced sealing strip, combined with a low locking force installation method, the customer eliminated the risk of enamelled flange damage, leakage and seal material creep, while improving equipment reliability and operational efficiency.